Siemens Energy has received an order for a steam turbine generator to be used in a waste-to-energy plant equipped with combined power and heat generation in Plymouth, England.

The customer is Imtech Deutschland GmbH & Co. KG, a leading provider of technical building services equipment, based in Planegg near Munich. As the general contractor for the Water-Steam-Cycle, Imtech will construct the plant for the Mannheim-based EfW specialist MVV Umwelt.

Once commissioned in 2014, the power plant – with an electrical capacity of up to 25 megawatts (MW) – is designed to cover the heat demand of Plymouth’s Naval Base, cost-effectively and with low CO2 emissions.

The waste-to-energy plant in Plymouth is expected to use 245,000 metric tonnes of household, business, and industrial waste to generate electricity and heat by means of combined heat and power generation to ensure a reliable heat supply for Plymouth’s Naval Base.

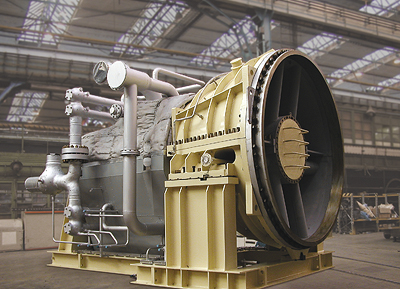

Construction of the power plant, with an installed electrical capacity of 25 MW and a maximum process steam extraction of up to 30 tones per hour, is scheduled to begin in the spring of 2012, with commissioning scheduled for 2014. Siemens is responsible for the delivery, installation, and commissioning of the SST-400 steam turbine, including gearboxes and oil system as well as the electrical generator and auxiliary systems. The steam generator installed in the plant produces steam that drives the turbine to ultimately produce electricity.

The plant is being built adjacent to the Naval Base in Plymouth in south west England. It will provide the base with a reliable and economical heat supply.

Additionally, most of the electrical energy produced will be used at the Naval Base. The British Defense Ministry’s Devonport Naval Base, located on the west side of the city, is the biggest naval port in Western Europe and also Plymouth’s biggest employer.

“The SST-400 is one of our most versatile industrial steam turbines,” said Markus Tacke, CEO of the Industrial Power Business Unit within Siemens Energy. “With an installed capacity of up to 65 MW, the flexible steam turbine has proven itself to be a cost-effective and environmentally friendly solution in a wide variety of applications.”