IBM’s Battery 500 project, led by scientists at IBM Research – Almaden in California, is an interdisciplinary consortium to develop a lithium–air battery that aims to increase the range of electrovehicles to 500 miles (approximately 800 km).

This is more than five times the range of today’s batteries, which average some 150 km per charge. If the project is successful, battery-powered vehicles could finally become a practical reality and thus overcome the main obstacle to becoming generally accepted and widespread: In a recent survey conducted by IBM, 64% of consumers said that the limited range was their strongest objection to driving electrovehicles.

Changing from gasoline to electricity as the main energy source for vehicles could be one of the most significant technological turning points in the history of our modern industrial society. However, progress has been slow in developing high-performance batteries. High manufacturing costs are another major factor that has limited the widespread acceptance and large-scale development of electrovehicles. Consumers’ greatest fear is being stranded somewhere with an empty battery, and this fear is justified, as the range of most current battery-operated vehicles is only some 150 km. It appears unlikely that a realistic range can be achieved with today’s battery technology, which must also have an acceptable weight and be available at reasonable prices.

Rechargeable lithium–ion storage batteries like the ones used in cell phones or notebook computers offer only a fraction of the energy density—the amount of energy that can be stored per mass unit or volume unit—achieved by fossil fuels such as gasoline or diesel. Therefore this battery technology for electrovehicles is only of interest today for short distances or in hybrid-engine vehicles. If this situation is to be fundamentally changed, new types of batteries with significantly higher energy densities must replace today’s lithium–ion batteries. IBM, world patent leader and active for decades in fundamental research, has launched a new project dubbed Battery 500 to tackle this problem. For this new project, IBM is leveraging its recent progress in the fields of materials science, nanotechnology, chemistry and supercomputing.

An interdisciplinary team of scientists at IBM Research – Almaden in California and IBM Research – Zurich, together with leading universities, corporations and research institutes has been exploring a so-called lithium–air battery since mid-2009. The aim of this project is to develop a battery whose energy density is up to ten times higher than that of today’s rechargeable lithium–ion batteries, thus providing electrovehicles with a range of up to 500 miles or 800 km. “With our lithium–air battery technology we hope to achieve a quantum leap that could be a breakthrough in electromobility,” explains Dr. Winfried Wilcke, initiator and head of the Battery 500 project at IBM Research – Almaden. “This is yet another project of IBM’s ‘Smarter Planet’ vision in which new mobility concepts play a vital role.”

“Airy” bundle of energy

A major advantage of the lithium–air battery is that it takes oxygen from the atmosphere as its reacting agent. The oxygen is stored in light carbon nanostructures in the cathode, meaning that significantly more energy per kilogram battery weight can be stored than in today’s batteries. A numerical example illustrates this advantage: a conventional lithium–ion battery with an energy content of 50 kilowatt hours (kWh) weighs about 500 kg. A range of 800 km would require an energy content of 150 kWh, which would mean a weight of 1.5 tons, which is clearly unrealistic for practical use in electrovehicles. In contrast, IBM scientists estimate that a 150 kWh lithium–air battery would weigh “only” about 150–300 kg.

The theoretically achievable specific energy of a lithium–air battery (without the weight of the ambient oxygen) is greater than 11 kWh per kilogram (kWh/kg). Scientists predict that, in practice, a lithium–air battery could achieve about one-tenth of the theoretical specific energy. Taking the relative efficiency of combustion motors and electromotors into account, the difference in “practical” energy densities between electromotors and gasoline or diesel-powered motors is actually very small because electromotors have a very high efficiency of 85%. The lithium–air technology thus exhibits the greatest potential of all battery types researched to date.

A battery that “breathes”

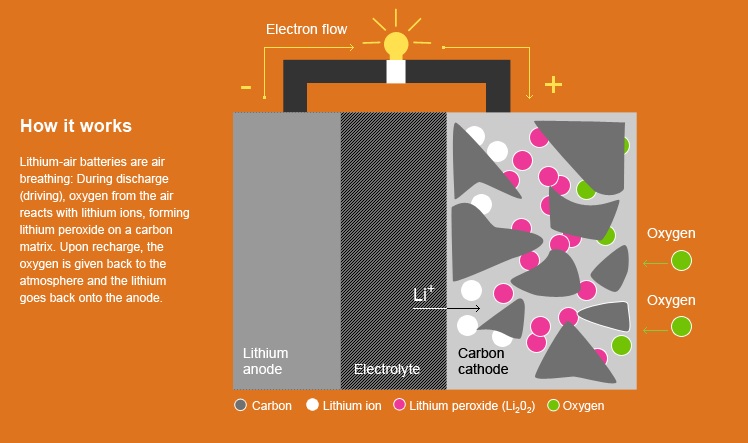

Like all batteries, the basic construction of a lithium–air battery consists of two electrodes, in this case a metal electrode of lithium (the anode) and an oxygen-permeable electrode of a light carbon structure (the cathode). When the battery is discharged, the lithium atoms of the anode lose electrons and proceed as lithium ions through an electrically conducting electrolyte to the cathode, where they react with oxygen from the atmosphere. The product of this reaction is then deposited in the cathode. When the battery is charged, it releases the oxygen collected while the vehicle was being driven (discharged) back into the atmosphere. Metaphorically speaking, the battery “inhales” oxygen while discharging and “exhales” it again while being recharged.

IBM scientists are focusing on so-called aprotic (non-watery) lithium–air batteries, which use organic liquids and lithium salts as electrolytes. Discharging the battery produces lithium peroxide (Li2O2)—but only when the right electrolytes are used—which is stored in the battery’s cathode. During the charging process, the lithium peroxide breaks down into oxygen, which is released into the atmosphere, and lithium, which is stored in the battery’s anode.

From simulations and experiments to success

The members of this project have already achieved major breakthroughs toward achieving their ambitious goal. For example, the functionality of this technology has been proved in principle on laboratory-scale models that unequivocally demonstrated the rechargeability of lithium–air batteries. The key to this first success was a combination of computer-based simulations and practical experiments. The team at the IBM Research – Zurich Laboratory performed so-called ab initio simulations to obtain new insights into the molecular-level processes that take place in lithium–air batteries. These highly complex simulations draw exclusively on basic laws of physics and physics models. In this way, interactions between atoms and molecules in a given system can be computed exactly. Performed on a petaflop IBM BlueGene/P supercomputer at Argonne National Laboratory, these simulations showed for the first time that the electrolytes used in conventional lithium–ion batteries do not work in lithium–air batteries, contrary to what was previously thought.

“Our simulations allowed us to demonstrate the processes that actually take place during discharge. The carbon-based electrolyte reacts in an undesirable manner with the lithium peroxide and decompose as a result. This effectively destroys the lithium–air battery,” explains Dr. Alessandro Curioni, head of the Computational Sciences research group at IBM Research – Zurich.

Using a mass spectrometer developed specifically for the Battery 500 project, scientists were able to perform laboratory experiments that clearly confirm the electrolyte decomposition predicted by the simulations. “Simulations and experimental results have allowed us to identify stable electrolytes with which we were able to demonstrate the basic functionality of the charging and discharging processes,” says project leader Wilcke. In addition, very high charge capacities have been demonstrated in the laboratory. A further fundamental result is the fact that, contrary to long-held assumptions, catalyzers are not kinetically necessary because the so-called overvoltage of the fundamental electrochemical reaction 2Li+ + O2 + 2-Li2O2 is much smaller than originally thought. Nevertheless, the very low conductivity of lithium peroxide is a problem that is yet to be resolved.

Still a “Grand Challenge”

Several other veritable challenges remain for scientists to solve before lithium–air batteries can be implemented for practical purposes or fabricated industrially. It is therefore one of IBM Research’s so-called “Grand Challenges”—ambitious and risky research projects with uncertain outcomes but very high potentials, such as the development of the WATSON supercomputer.

Currently, scientists are seeking to increase the energy density of the battery, which is still far too low for real-life electromobility. Another challenge is the charging process, which is currently too slow. But even assuming that this can be improved markedly, it will not be possible, say, to charge the battery quickly during one’s coffee break. Scientists are currently aiming for the capability to charge the battery overnight, which, based on the considerable range, should be sufficient. To solve the problem posed by lithium’s susceptibility to humidity, the IBM team is also developing novel nanomembranes, which will be required in order to protect the sensitive lithium anode from steam and carbon dioxide in the atmosphere. Additional challenges are the long-term stability of the components’ materials and the improved ability to suppress undesirable secondary reactions.

Upon successful completion of the current research phase, the Battery 500 project could possibly be pursued with industrial partners to develop commercial models of the lithium–air battery in the timeframe of 2020 to 2030.