The science of light and liquids has been intimately entwined since Léon Foucault discovered the speed of light in 1862, when he observed that light travels more slowly in water than in air.

This physical harmony between the two materials is now being harnessed to collect and drive light to where it can be the most useful. October’s issue of Nature Photonics focuses on optofluidics, the study of microfluidics—the microscopic delivery of fluids through extremely small channels or tubes—combined with optics. In a review written by Demetri Psaltis, Dean of EPFL‘s School of Engineering, he and his co-authors argue that optofluidics is poised to take on one of this century’s most important challenges: energy.

“By directing the light and concentrating where it can be most efficiently used, we could greatly increase the efficiency of already existing energy producing systems, such as biofuel reactors and solar cells, as well as innovate entirely new forms of energy production” explains Psaltis. “EPFL is the world leader in optofluidics, our institution is in a position to develop truly efficient and disruptive energy sources.”

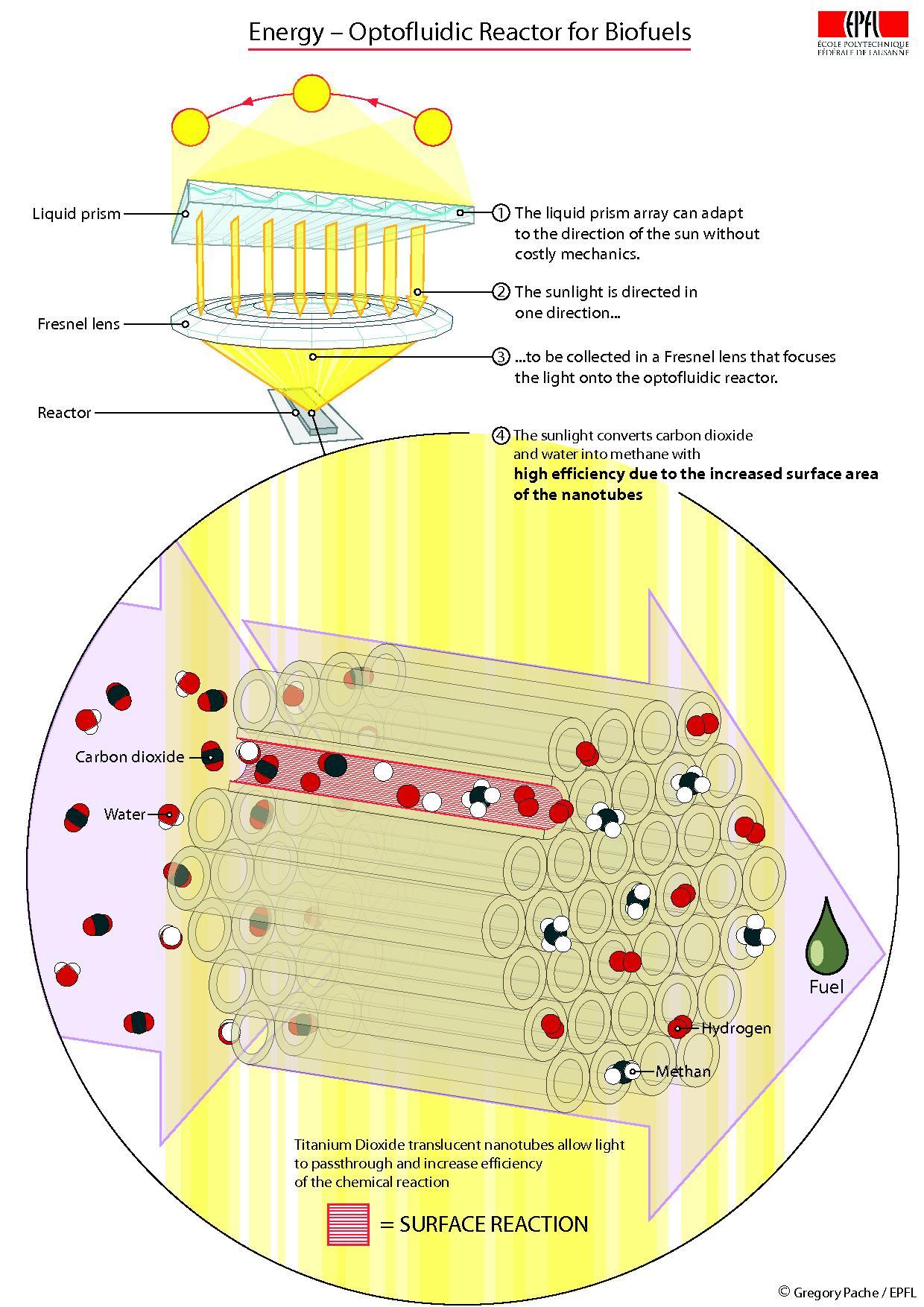

Sunlight is already used for energy production besides conventional solar panels. For example, it is used to convert water and carbon dioxide into methane in large industrial biofuel plants. Prisms and mirrors are commonly employed to direct and concentrate sunlight to heat water on the roofs of homes and apartment buildings. These techniques already employ the same principles found in optofluidics—control and manipulation of light and liquid transfer—but often without the precision offered by nano and micro technology.

A futuristic example: Optofluidic solar lighting system

How can we better exploit the light that hits the outside of a building? Imagine sunlight channelled into the building An optofluidic solar lighting system could capture sunlight from a roof using a light concentrating system that follows the sun’s path by changing the angle of the water’s refraction, and then distribute the sunlight throughout the building through light pipes or fibre optic cables to the ceilings of office spaces, indoor solar panels, or even microfluidic air filters. Using sunlight to drive a microfluidic air filter or aliment an indoor solar panel—which would be protected from the elements and last longer—is a novel way to use solar energy to supplement non-renewable resources.

In such a system, it would be essential to deviate from the secondary devices such as air filtrage and solar panels to maintain a comfortable constant light source for ceiling lighting—the flickering of the light source due to a cloud passing over would be intolerable. In order to modulate these different channels to maintain a constant light source, a system using electrowetting could deviate light from one channel into another both easily and inexpensively. A droplet of water sits on the outer surface of light tube. A small current excites the ions in the water, pushing them to the edge of the droplet and expanding it just enough for it to touch the surface of another tube. This expanded droplet then creates a light bridge between the two parallel light tubes, effectively moderating the amount of light streaming through either one.

Up-scaling for industrial use

“The main challenge optofluidics faces in the energy field is to maintain the precision of nano and micro light and fluid manipulation while creating industrial sized installations large enough to satisfy the population’s energy demand,” explains David Erickson, professor at Cornell University and visiting professor at EPFL. “Much like a super computer is built out of small elements, up-scaling optofluidic technology would follow a similar model—the integration of many liquid chips to create a super-reactor.”

Since most reactions in liquid channels happen at the point of contact between the liquid and the catalyst-lined tubes, the efficiency of a system depends on how much surface area is available for reactions to take place. Scaling down the size of the channels to the micro and nano level allows for thousands more channels in the same available space, greatly increasing the overall surface area and leading to a radical reduction of the size needed (and ultimately the cost) for catalytic and other chemical reactions. Adding a light source as a catalyst to the directed flow of individual molecules in nanotubes allows for extreme control and high efficiency.

Their review in Nature Phontonics lays out several possibilities for up-scaling optofluidics, such as using optical fibers to transport sunlight into large indoor biofuel reactors with mass-produced nanotubes. They point out that the use of smaller spaces could increase power density and reduce operating costs; optofluidics offers flexibility when concentrating and directing sunlight for solar collection and photovoltaic panels; and by increasing surface area, the domain promises to reduce the use of surface catalysts—the most expensive element in many reactors.