As the world moves toward greater use of low-carbon and zero-carbon energy sources, a possible bottleneck looms, according to a new MIT study: the supply of certain metals needed for key clean-energy technologies.

Wind turbines, one of the fastest-growing sources of emissions-free electricity, rely on magnets that use the rare earth element neodymium. And the element dysprosium is an essential ingredient in some electric vehicles’ motors. The supply of both elements — currently imported almost exclusively from China — could face significant shortages in coming years, the research found.

The study, led by a team of researchers at MIT ’s Materials Systems Laboratory — postdoc Elisa Alonso PhD ’10, research scientist Richard Roth PhD ’92, senior research scientist Frank R. Field PhD ’85 and principal research scientist Randolph Kirchain PhD ’99 — has been published online in the journal Environmental Science & Technology, and will appear in print in a forthcoming issue. Three researchers from Ford Motor Company are co-authors.

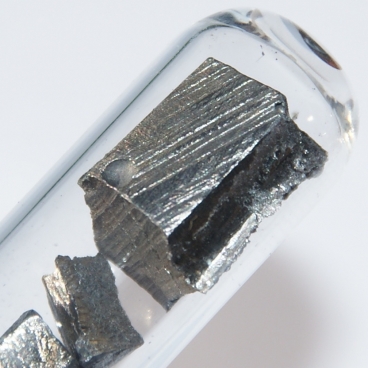

The study looked at 10 so-called “rare earth metals,” a group of 17 elements that have similar properties and which — despite their name — are not particularly rare at all. All 10 elements studied have some uses in high-tech equipment, in many cases in technology related to low-carbon energy. Of those 10, two are likely to face serious supply challenges in the coming years.

The biggest challenge is likely to be for dysprosium: Demand could increase by 2,600 percent over the next 25 years, according to the study. Neodymium demand could increase by as much as 700 percent. Both materials have exceptional magnetic properties that make them especially well-suited to use in highly efficient, lightweight motors and batteries.

A single large wind turbine (rated at about 3.5 megawatts) typically contains 600 kilograms, or about 1,300 pounds, of rare earth metals. A conventional car uses a little more than one pound of rare earth materials — mostly in small motors, such as those that run the windshield wipers — but an electric car might use nearly 10 times as much of the material in its lightweight batteries and motors.

Currently, China produces 98 percent of the world’s rare earth metals, making those metals “the most geographically concentrated of any commercial-scale resource,” Kirchain says.

Historically, production of these metals has increased by only a few percent each year, with the greatest spurts reaching about 12 percent annually. But much higher increases in production will be needed to meet the expected new demand, the study shows.

China has about 50 percent of known reserves of rare earth metals; the United States also has significant deposits. Mining of these materials in the United States had ceased almost entirely — mostly because of environmental regulations that have increased the cost of production — but improved mining methods are making these sources usable again.

Rare earth elements are never found in isolation; instead, they’re mixed together in certain natural ores, and must be separated out through chemical processing. “They’re bundled together in these deposits,” Kirchain says, “and the ratio in the deposits doesn’t necessarily align with what we would desire” for the current manufacturing needs.

Neodymium and dysprosium are not the most widely used rare earth elements, but they are the ones expected to see the biggest “pinch” in supplies, Alonso explains, due to projected rapid growth in demand for high-performance permanent magnets.

Kirchain says that when they talk about a pinch in the supply, that doesn’t necessarily mean the materials are not available. Rather, it’s a matter of whether the price goes up to a point where certain uses are no longer economically viable.

The researchers stress that their study does not mean there will necessarily be a problem meeting demand, but say that it does mean that it will be important to investigate and develop new sources of these materials; to improve the efficiency of their use in devices; to identify substitute materials; or to develop the infrastructure to recycle the metals once devices reach the end of their useful life. The purpose of studies such as this one is to identify those resources for which these developments are most pressing.

While the raw materials exist in the ground in amounts that could meet many decades of increased demand, Kirchain says the challenge comes in scaling up supply at a rate that matches expected increases in demand. Developing a new mine, including prospecting, siting, permitting and construction, can take a decade or more.

“The bottom line is not that we’re going to ‘run out,’” Kirchain says, “but it’s an issue on which we need focus, to build the supply base and to improve those technologies which use and reuse these materials. It needs to be a focus of research and development.”

Barbara Reck, a senior research scientist at Yale University who was not involved in this work, says “the results highlight the serious supply challenges that some of the rare earths may face in a low-carbon society.” The study is “a reminder to material scientists to continue their search for substitutes,” she says, and “also a vivid reminder that the current practice of not recycling any rare earths at end-of-life is unsustainable and needs to be reversed.”