Researchers have tapped a novel material to develop a low-cost, efficient, and environmentally friendly solar cell.

Researchers have tapped a novel material to develop a low-cost, efficient, and environmentally friendly solar cell.

In particular, the device is the first to solve the problem of the Grätzel cell, a promising technology with a significant disadvantage: it leaks. The dye-sensitized cell’s electrolyte is made of an organic liquid, which can leak and corrode the solar cell itself.

Grätzel cells use a molecular dye to absorb sunlight and convert it to electricity, much like chlorophyll in plants. But the cells typically don’t last more than 18 months, making them commercially unviable. Researchers have been searching for an alternative for two decades. At Northwestern University, nanotechnology expert Robert P. H. Chang challenged chemist Mercouri Kanatzidis with the problem of the Grätzel cell. Kanatzidis’ solution was a new material for the electrolyte that actually starts as a liquid but ends up a solid mass. Thus, the new all solid-state solar cell is inherently stable.

“The Grätzel cell is like having the concept for the light bulb but not having the tungsten wire or carbon material,” says Kanatzidis, of the need to replace the troublesome liquid. “We created a robust novel material that makes the Grätzel cell concept work better. Our material is solid, not liquid, so it should not leak or corrode.”

Postdoctoral fellow In Chung in the Kanatzidis group worked closely with graduate student Byunghong Lee in the Chang group to develop the new cells, achieving performance gains that amounted to approximately 1 percent per month.

In the new cell, a thin-film compound made up of cesium, tin and iodine, called CsSnI3, replaces the entire liquid electrolyte of the Grätzel cell. Details are reported in the journal Nature.

“This is the first demonstration of an all solid-state dye-sensitized solar cell system that promises to exceed the performance of the Grätzel cell,” says Chang, a senior author of the paper. “Our work opens up the possibility of these materials becoming state of the art with much higher efficiencies than we’ve seen so far.”

‘Room to grow’

The new cell exhibits the highest conversion efficiency (approximately 10.2 percent) so far reported for a solid-state solar cell equipped with a dye sensitizer. This value is close to the highest reported performance for a Grätzel cell, approximately 11 to 12 percent. (Conventional solar cells made from highly purified silicon can convert roughly 20 percent of incoming sunlight.)

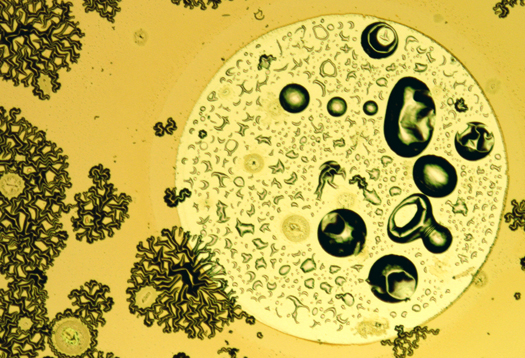

Unlike the Grätzel cell, the new solar cell uses both n-type and p-type semiconductors and a monolayer dye molecule serving as the junction between the two. Each nearly spherical nanoparticle, made of titanium dioxide, is an n-type semiconductor. Kanatzidis’ CsSnI3 thin-film material is a new kind of soluble p-type semiconductor.

“Our inexpensive solar cell uses nanotechnology to the hilt,” Chang says. “We have millions and millions of nanoparticles, which gives us a huge effective surface area, and we coat all the particles with light-absorbing dye.”

A single solar cell measures half a centimeter by half a centimeter and about 10 microns thick. The dye-coated nanoparticles are packed in, and Kanatzidis’ new material, which starts as a liquid, is poured in, flowing around the nanoparticles. Much like paint, the solvent evaporates, and a solid mass results. The sunlight-absorbing dye, where photons are converted into electricity, lies right between the two semiconductors.

Chang chose to use nanoparticles approximately 20 nanometers in diameter. This size optimizes the device, he says, increasing the surface area and allowing enough space between the particles for Kanatzidis’ material to flow through and set.

Technically, this new cell is not really a Grätzel cell since the hole-conducting material CsSnI3 is itself light absorbing. In fact, the material absorbs more light over a wider range of the visible spectrum than the typical dye used in Grätzel cells. In the Kanatzidis-Chang cell, the CsSnI3 plays an additional role in the operation of the cell that is not played by the liquid electrolyte couple, and that role is light absorption.

“This is only the beginning,” Chang says. “Our concept is applicable to many types of solar cells. There is a lot of room to grow.”

The lightweight thin-film structures are compatible with automated manufacturing, the researchers point out. They next plan to build a large array of the solar cells.

The National Science Foundation, the U.S. Department of Energy and the Initiative for Energy and Sustainability at Northwestern (ISEN) supported the research.