The European HySYS (Fuel Cell Hybrid Vehicle System Component Development) project aims to take stock of the elements needed to manufacture an electric vehicle whose electricity is generated by a fuel cell. The fuel cell on board is powered by air and hydrogen.

This blend produces a physico-chemical reaction that generates electricity and water as a byproduct. The elements needed to manufacture the HySYS vehicle are linked to the correct functioning of the vehicle’s fuel cell and electric engine. It first means developing a hydrogen battery on the scale of the vehicle. The elaboration of a system that converts alternating current into direct current.

It also means manufacturing a coherent electric engine in terms of power and travel needs and in the power generated by the vehicle. Finally the research has developed a system for stocking the hydrogen as well as a reserve system for part of the electricity generated by the fuel cell. But for the entire system to be viable, it must be outfitted with a high-performance safety system that can sound the alarm in the case of a hydrogen leak in the vehicle.

Dr. Jörg WIND, Daimler AG, Germany is the HySYS project coordinator explains the advantages of the HySYS vehicle.

Which are the advantages of fuel cell vehicles?

The performance of vehicles with fuel cells is twice as high as those with combustion engines. So we reduce fuel consumption by a factor of 2. What’s more, it’s possible to significantly reduce CO2 emissions, or green gas emissions due to road traffic.

This also holds if we generate the hydrogen we need for the fuel cell vehicle using fuel, more specifically, by fuel reforming. On the other hand, there will still be part of fossil energies coming from fuel. But if we generate hydrogen using regenerating energy sources, we’re able to reduce greenhouse gas emissions even more efficiently.

Hydrogen can also be manufactured using wind energy, or from biomass. In this way, we cover two themes that are currently very important: on the one hand, reduction of energy consumption for road traffic, and on the other emission reduction. What’s more, fuel cell vehicles are very quiet. So it’s a real advantage for big cities because they make less noise.

Developing the HySYS prototype took the expertise of 28 European partners – including universities and manufacturers. Each component was designed to reduce future production costs and optimize the vehicle’s performance. Can you better explain how the HySYS vehicle functions?

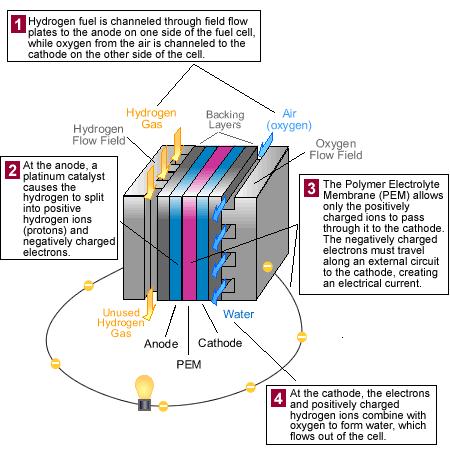

An electrochemical reaction takes place inside the fuel cell. The hydrogen frees its electrons and its chemical energy is transformed into electric energy. These electrons are then transported by an exterior electrical circuit – by the wiring – to the electric motor.

The electric motor receives the electrical current by the fuel cell system, more specifically, by the fuel cell stack. For this, the stack needs the hydrogen from the hydrogen tanks and oxygen from the ventilation system.

Here, in the humidifier, the oxygen is humidified and powers the stack. Indeed, the hydrogen, which here comes from the tank, frees its electrons. These electrons can then be transported by the wiring to the electric motor.

Using hydrogen in a car does carry certain risks. Has the HySYS project planned safety systems?

Hydrogen is a dangerous, volatile gas that explodes at concentrations greater than 4% in the air and ignites at concentrations greater than 9% in the air. But for a hydrogen leak to be potentially dangerous, the gas has to come in contact with a spark or a hot spot in the car.

To avoid such a risk, scientists have developed ultra-sensitive sensors able to detect as little as 1% hydrogen in the ambient air of the car and sound the alarm in case of danger. The HySYS project has planned a safety system to compensate for a potential hydrogen leak.

If the sensors detect a leak, the hydrogen supply is automatically shut off and the driver is told to get out of the car. This safety system has been designed in keeping with European norms and current highway legislation, as well as to reassure the public at large about the use of this type of vehicle.

Frédéric FAVIER, chemical researcher CNRS, University of Montpellier partner in the HySYS project and responsible for sensor testing, explains how the hydrogen nanosensors work

The hydrogen safety sensors are located near the hydrogen tanks, but are also positioned all around the inside of the car. The sensors are able to detect the presence and quantity of hydrogen in its environment. The sensitive component is based on a precious metal called palladium.

The sensor, in terms of cost, is limited because we’re dealing with nanotechnology, so there’s very little metal used on the sensitive components, on the sensors, and palladium really sponges up hydrogen. In the presence of hydrogen, palladium undergoes a chemical reaction and is converted to palladium hydride – its physical and chemical properties are changed from metal palladium.

And it’s this chemical reaction, of palladium into palladium hydride, that this system detects.

What happens if the risk threshold is reached?

The palladium sensors are designed to react at 25% of the risk threshold, so at a concentration of 1% hydrogen in the air (25% of 4% =1%). At a concentration of 1% hydrogen in the air, the embedded computer shuts off the engine and hydrogen supply valves and sends a signal to the driver telling him to get out of the car.

The sensors are also designed to react quickly to avoid the rapid progression from 1% to 4% hydrogen in the car. Finally, these sensors are tested to recognize only hydrogen and avoid parasite gases.