TU Delft is leading a new project sponsored by the European Commission in which research institutes, universities and the battery and automotive industry from 8 European countries will join forces to develop cheaper and safer rechargeable batteries with higher energy density and power performance. With this research, the consortium partners aim to pave the way for widespread use of electric vehicles. The EuroLiion project will run for four years and has a budget of 5.5 million Euros.

Rechargeable Lithium-ion batteries used in today’s electric vehicles have a number of disadvantages that prevent electric vehicles to be introduced on a large scale. The batteries are for example expensive, heavy and they have limited capacity. In the EuroLiion project research institutions, universities and the battery and electric vehicles industry from 8 different European countries are aiming to solve the current disadvantages by developing a lighter, more flexible and cost effective battery system with high power performance and energy density. These batteries can be used in all sorts of electric vehicles, ranging from lorries and buses to cars and motorcycles. With this research, the consortium partners aim to make mass production of electric vehicles viable.

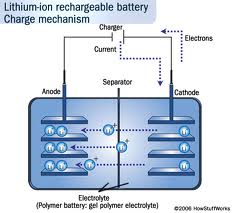

The research described in this proposal aims to develop a new Li-ion batteries for electric vehicles with the following characteristics: ‘High energy density of at least 200 Wh/kg ‘Low costs that is, a maximum of 150 Euro/kWh ‘Improved safety Although the Li-ion batteries appears to be the most appropriate technology to meet these goals, considerable research and development is required. For example, the much-used LiFePO4 cells cannot reach the energy density criterion, and in addition, LiFePO4 is patented, which hampers worldwide commercialisation. Many other materials are either too expensive or do not meet current safety, environmental standards (e. g. , cobalt in LiCoO2). Thus, we propose a shift from carbon to the much higher capacity silicon-based anodes, and from cobalt-based to iron and/or manganese/nickel-based cathodes, and to use novel electrolyte salts.

To successfully develop a European Li-ion technology, the R&D will start at the anode side, that is Si, with a LiFePO4-C material at the cathode side. This requires a new electrode formulation with respect to binder, electrolyte salt, solvent, and composition. The change in formulation at the anode and electrolyte allows for a change in the cathode materials ‘ and a series of both novel (e. g. , fluorosulfates, LiFeSO4F) and more established systems, will be investigated. New synthetic routes are proposed, along with an extensive characterization program. Scale-up, testing and benchmarking of optimum formulations will be performed. The outcome will be a newly developed battery, manufactured and tested by end-users.

The new batteries consists of:

- a newly formulated Si-negative electrode,

- newly designed low cost salts, and

- modified positive electrodes.

To achieve these goals, the consortium includes renowned universities and knowledge institutes; a SME battery producer and the electric vehicles industry as end-users. Thus, the composition of the consortium covers the whole spectrum of R&D, manufacturing and testing.

The EuroLiion project is coordinated by TU Delft and sponsored by the European Commission. The total budget is 5.5 million Euros of which 4 million are a contribution from the European Commission. The project will run for four years and is part of the European Framework 7 programme.