Zinc Air Inc. (ZAI) announced that it had obtained exclusive rights from Lawrence Livermore National Laboratory for the zinc air fuel cell (U.S. Patent 5,434,020) invented by John Cooper, a retired Lawrence Livermore National Laboratory chemist.

A fuel cell is typically similar in operation to a conventional battery, although they have some distinct physical differences. Primarily, a fuel cell is an electro-chemical device wherein the chemical energy of a fuel is converted directly into electric power. The main difference between a conventional battery and a fuel cell is that, unlike a battery, a fuel cell is supplied with reactants externally. As a result, whereas a battery is discharged, a fuel cell never faces such a problem, as long as the supply of fuel is provided.

The zinc air fuel cell consumes zinc metal and atmospheric oxygen, and produces a reaction product consisting of a liquid suspension of zinc oxides and potassium zincate in an alkaline electrolyte.

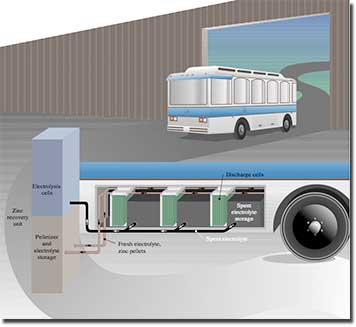

Refueling is accomplished by replacing the spent electrolyte with fresh electrolyte and zinc pellets.

During discharge, zinc pellets fall continuously from the overlying hopper into a narrow opening at the top of each cell. Because the cell gap is only a few times larger than the particles, the particles do not close pack–even when subjected to strong vibrations. Electrolyte flows upward through the cell and hopper to remove heat and reaction products.

“At the moment, most in the auto industry are currently looking to lithium batteries as the power solution for electric vehicles, but those batteries are manufactured primarily outside of the United States and are not cost effective for widespread use,” said ZAI Co-Founder and President Dave Wilkins. “There is enough readily available zinc just in the United States to produce billions of these batteries,” he continued.

By contrast, lithium primarily is found outside the United States.

Worldwide resources of zinc total more than 1.8 gigatons – with more than 35 percent of that in the United States alone.

Global zinc production in 21 months would be sufficient to produce one billion 10 kWh zinc air batteries – by contrast it would take 180 years of lithium production to produce those same batteries. These figures were quoted in a recent white paper by Meridian International Research, which stated, “Lithium supply and future production will be far from adequate to sustain global electric vehicle production.”

According to Cooper, “In the short-term, this new technology has the potential to positively impact fleets of electric vehicles, such as FedEx, UPS and the U.S. Postal Service, that combine high daily usage, low-power requirements, and an in-place service infrastructure.” There is an enormous market for lightweight, low-power, zero-emission delivery vehicles that can operate multiple shifts. Rapid refueling – as opposed to overnight recharging – makes multiple shifts a reality. With 10-minute refueling, this technology allows battery use up to 24 hours a day.

The technology enables safe, lower-cost, clean, quiet, reliable and environmentally friendly power generation. Zinc Air Fuel Cell (ZAFC) products combine atmospheric oxygen from the air we breathe with zinc metal pellets as the fuel to generate electricity.

In operation, the fuel cell consumes all of the zinc and is operationally quiet, providing instantaneous electrical energy with no greenhouse gas emissions. It also doesn’t contain any of the toxic elements found in lithium batteries or other battery chemistries.

“In truth, new technology often matures in fits and starts over decades,” observes Annemarie Meike, the business development executive who has stewarded the development of this and other clean tech at LLNL. “A previous licensee brought marketing and manufacturing expertise to our inventions. Some of that developmental understanding will seep into new incarnations of the zinc air fuel cell.”

Zinc Air technology is now seeing life because of the anticipated demand for efficient, low-cost alternatives to lithium for electric vehicle battery production. One of the many benefits of this technology is that it enables continuous fuel feed while the system is under load, making it ideal for electronic vehicle and fleet power supply.

This technology on a small scale also may provide portable power as a generator (1-3 kW) or can be scaled up to provide enough power to operate high-use fleet vehicles and buses.

ZAI is in discussions with multiple fleet vehicle manufacturers to develop products for their immediate needs. The company intends to begin development and testing in late 2010 with full-scale field testing in the second quarter of 2011.

The next time I read a blog, I hope that it doesnt disappoint me as much as this one. I mean, I know it was my choice to read, but I actually thought youd have something interesting to say. All I hear is a bunch of whining about something that you could fix if you werent too busy looking for attention.